PEOPLE

To pass the baton to the next generations,From 5th to 6th and beyond.

Connecting generations from the 5th generation to the 6th generation and into the future

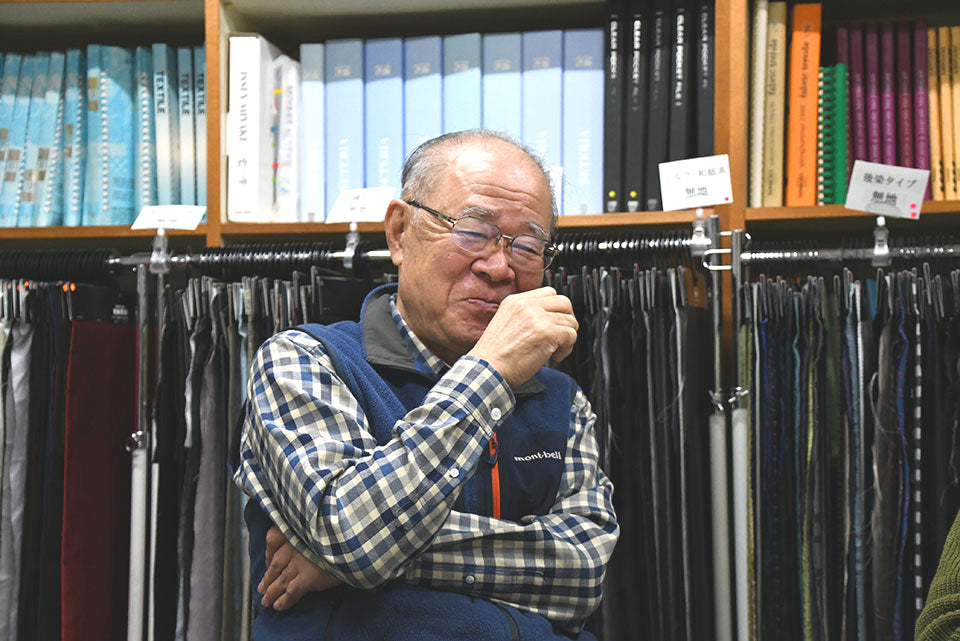

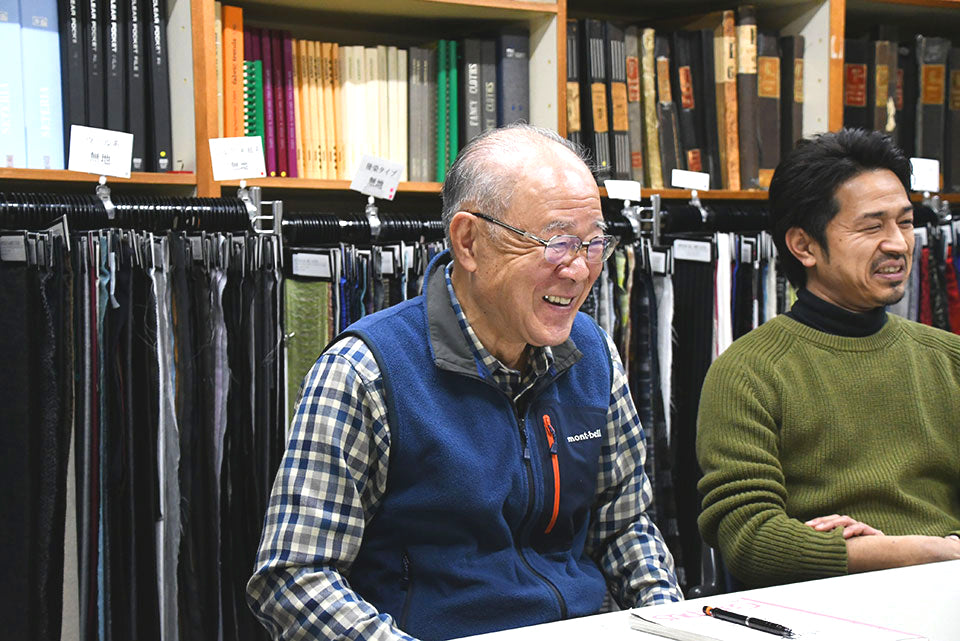

This is the interview of 5th president and his 2 sons about the history of Makita shoten and the thought toward next generation.

Q:How long has been working in Makita Shoten, Mr.President?

Norio: It's been 40 years already.I am from Niigata originally, got married with my wife to be a family of Makita. At that time, Makita was wholesaler and we sold the textiles of this region. Our main products were umbrella textile but I was in charge of stole textile since the trend of stoles were growing in the market.

Also we produced the garment textile, using polyester warp of umbrella combined with silk weft, it became big sales. So our domain became textiles for umbrella, stole and garment. It was the era of made in Japan.

Q: But the time changed.

Norio: As you know, the amount of overseas production increased.It is because of the growth of OEM and also new movement in fashion industry like fast fashion, it chased the lower price.

Also our umbrella business faced the changes.

It was the licensing business,from original planning to realization of clients' requests.

Yoichi: I remember big amount of textile stocks for clients' brands.

Norio: In this trend of time, our competitors and business partners expanded the overseas productions.

Yoichi: And we were also invited to join this trial in abroad.

Q:But you did not do overseas productions.

Norio: No. we stayed Nishikatsura Gunnai and kept on our productions here.

If we tried abroad, we might get big change but I assume it would not last long.

We are regional company, who were born and grew up, worked and lived here. That is Makita Shoten.

Q:Then did you try something instead?

Norio: we wanted to create something we only could do.

That is why we invested to machines. We started to plan and design inhouse and manufacture in our factory, for that, we bought electric jacquard machines even they were quite expensive at that time.

We did not think of the competition with China, we tried to create something original.

Q:It was the brave decision of president!

Norio: It was not me. It is Makita Shoten itself, that has been investing people, talent and equipment for creativity.

Also we were supported by this region, that is why we could challenge bravely.

Q:talking about garments' textile, you have been working with international apparel company.

Norio: Yes, it was also because of our electric jacquard machines.

The designer of this apparel brand had looked for the factory who could weave complicated new textile using electric jacquard machine and he found we had 6 machines and that is how we had started to create his new textile using one of our machines.

Yoichi: at that time, we had big amount of order for umbrella textiles using special yarn combination, our craftsman wanted to use all the machines for that production but we insisted to use one of them for creating garment textile for this designer.

Norio: It is much easier to weave umbrella textiles but on the other hand, garment textiles require finer yarn count like polyester, silk, and cupro as well as cotton, linen and wool, it caused irregularity and also took longer to sell.

Tetsuya: Compared with umbrella textile weaving, garment textile took longer time and looked less efficient for experienced weavers of our factory.

Q:From the management point of view for president, it is surprising that you did not give up this challenge.

Norio: I like creativity after all. Of course I wanted to get the knowhow about garment textile but I was so impressed with the passion of the designer and it was simply happy to create something new together.

It is very important who to work with.

And later, this brand welcomed new designer and we kept working together, improving our technique, technology and ideas more.

And when we were invited to his collection show, he told us that we could come together all the way. I was honored to hear that.

Q:Makita Shoten respects people and creativity. The story sounds like very successful but I heard you had also very tough moment.

Yoichi: I am the first son and after experienced in other company, I came back to Makita Shoten, it was just after Lehman shock and I saw the production of garment textile decreased first, and after 1 year umbrella textiles, even when we just opened our second weaving factory.

Tetsuya: I am the second son and I came back to my house 1 year earlier than my brother but I remember the big change before Lehman shock and after.

Yoichi: It was the moment that Makita Shoten thought again what we did and what we could do.

Norio: I was grateful that our business partners kept the relationship with us even if the situation had changed. Lehman shock was tough and caused our employees hardship but I found it was the chance to think of ourselves to start something new.

OEM works were helpful but it might not be stable so that we thought of re-thinking our way of working.

Q:Yoichi and Tetsuya, it might be quite a challenge to take over your family business.

Tetsuya: My brother has been told to take over our business since he was a teenager and on the other hand, I was quite free to choose my life. But when I was working in other company, I had a chance to show our umbrella and realized that I knew few about our business and also my colleague at that time asked me why I would not work in my family since he found our business so inspiring.

Yoichi: I have decided to come back to my family so that I experienced in other company after graduation.

Tetsuya: I remember my brother wrote in his essay when he was in elementary school, he wrote " I will be a president of my family company!"

Norio: I felt that the reaction of our partner companies changed after my sons came back to work with me. They respected us that Makita Shoten had a future. I was so grateful about that.

Yoichi: I found our company's worth since I experienced other company.

I heard many compliments that Makita Shoten created beautiful things.

Tetsuya: I met my friends since kids age when I came back to my region, I again found how wonderful to live and work here.

Yoichi: the sky is beautiful, sounds of river is pleasant. I wake up in the morning and I feel happiness on my way to work. Of course the work is tough but I found it interesting. Recently, we have more chance to meet new clients and we create together and we sell by ourselves.

Q:I see Makita Shoten's pop up events and shops in Tokyo as well as media information a lot recently.

Yoichi: It is great but we have a jinx that we better not to be too noticed.

Tetsuya: it is said that too flashy is not for us.

Norio: we experienced oil shock when we build our main office.

Yoichi: I guess the best balance is just noticed by our dear clients only.

Q:what is the aim for the future when you pass the baton to the next generations?

Norio: I want to sell our umbrellas more since it represents our manufacturing.

Tetsuya: I often think that it will be nice to see our textiles everywhere in the region as we welcome many tourists and clients nowadays.

Yoichi: I want to tell my kids that you will take over this company without any anxiety. There is a pressure to take over the long history but it is the happiness as well. We have our employees and they are our strength to move on.

Tetsuya: we have more family last 10 years.

Yoichi: when we were kids, we were not allowed to stay in the office but now we see our kids staying with us beside our working space.

Since we keep the line between private and public but I found it is important to involve young generation to our working situation and I believe it will be the DNA to keep our history.

Norio: I am grateful to see women staffs keep working even after they have children and it is great that different generations all work together.

Presenting the manufacturing opportunity to the next generation, that is the Makita shoten itself.

Other articles

Fujie: Connecting the vision of textile artisans and brands to create something

>Read the article

The charm and fun of weaving learned through umbrella making: Rika Takiguchi

> Read article

What is the customer service at Makita Shoten like from the sales team?

> Read article

Interview with a team of umbrella craftsmen about manufacturing in Makita

> Read article

Interview with the planning team about working at Makita Shoten

> Read article

Makita Shoten's textiles evolve into a new era

<Ordering original fabric>

[For corporate customers only] Would you like to create your own original jacquard fabric? We have a textile designer with specialized knowledge who will support you, so even if you are new to fabric making, you can place an order.