PEOPLE

Made by the neighbors.

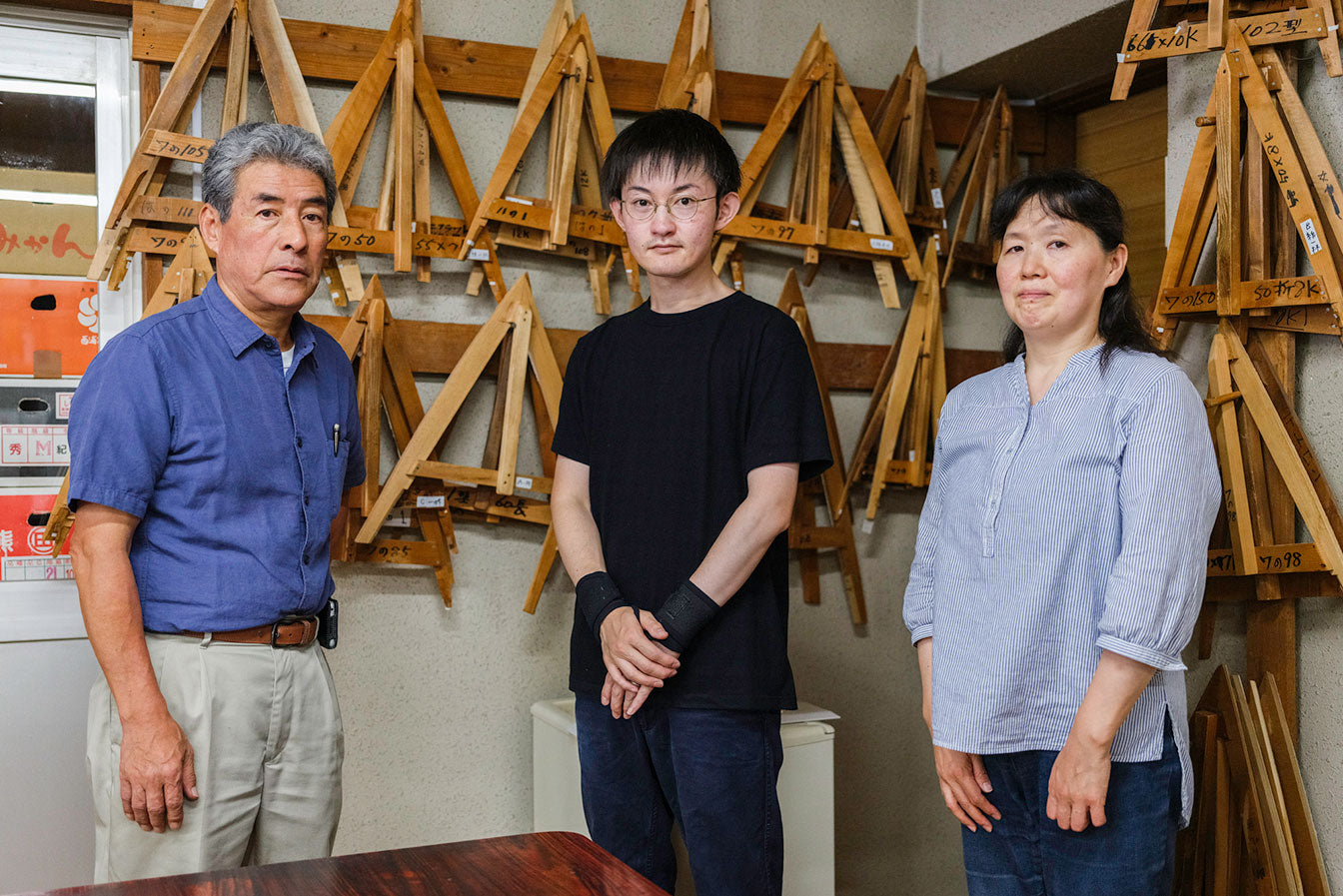

Interview with a team of umbrella craftsmen about manufacturing in Makita

Makita teamwork supported by Nishikatsura and Gunnai

Two people, one who has been involved in the umbrella business for 30 years and the other a young craftsman who has been working as a professional umbrella fabric cutter for six years, talk about the appeal of Makita umbrellas.

Q:What made you start working in this company?

Sugaya: I think we are all neighbors.Takao: I am the youngest member in this team. After working in Tokyo for 10 years, I visited Makita and started working since then.

Q: Do you have any reason that you choose Makita?

Takao: Of course it was my neighbor company but when our president introduced me the job in the umbrella team, I was fascinated with the charm of making umbrella, especially its various processes. I could choose the textile weaving team but I was interested in making umbrellas.

Sugaya: when Takao started working here, the elder craftsmen just retired.

Takao: yes, so Chika is my closest colleague even she is much mentor.

Chica: we used to produce hundreds of same umbrellas because it was the mass production era but we needed to set up our new production style with the change of time.

Sugaya: we used to sell the umbrella textiles that we designed, planned and made maquette by ourselves. But after, license business expanded and we shifted our creativity from creating original design to realization of clients' requests. And now, we become like umbrella making professional team who can create from vague idea to real & charming umbrella.

Q:This is because of Makita who has an experience of whole processes, from planning, weaving to finishing umbrella.

Takao: Yes, I think so. There are various patterns of shapes, bones and combination in umbrellas. Makita can do whole process from weaving original fabric to cutting, sewing and finishing in our factory as well as collaboration with neighbor area, Nishikatsura, Fujiyoshida and Tsuru region.

Sugaya: many other factories stopped production and made them in cheaper countries in abroad. But Makita kept our policy ~made in our region~ and kept the production facilities.

Chika: we can answer the various requests because of this policy, I believe.

Sugaya: recently, we get more and more contact from companies and creators who want to make new umbrella with us.

Q:there are lots of cheap umbrellas in the market but you get more requests. What is the reason?

Sugaya: I think there are umbrellas but not good ones so much in the market. We show ours in the spiral market and we get good compliments like " I never saw such beautiful umbrellas!" from clients.

Takao: clients are from young generation to elders.

Chika: you can find our umbrella on the street easier. Ours are outstanding.

While we are talking, other staffs also joined.

Managing director: once I was sitting in the train, the young woman standing in front of me had our umbrella. I was so happy that I wanted to tell her it was ours.

Staff: when I was passing by the street in Tokyo, I recognized our 1866 umbrella with elder beautiful woman. It is easy to tell because its shimmer, color and texture even from far away.

Takao: As the craftsman, I am happy to make it, sell it and when I see someone using it, it is the happiest moment.

Sugaya: we make umbrellas with care and love so that we hope everyone can enjoy it for long time. For that, we support clients with after care and repair.

Q:There are a lot of umbrella in Makita and it is hard to choose one!

Sugaya: Yes,we have plenty!

Takao: since we have the basic shape, we adjust them one by one to fit with textile more.

Q:I found you cut the textile by hand, not using machine.

Takao: human hand is more precise than machine. We have various textiles so that hand and knife is the best tool for the precise cutting.

Chika: you keep using very old knives.

Takao: normally such old knives are not usable anymore but for some textile, this length of blade is the best.

Q:how do you manage such variation?

Sugaya: it is Chika

Chika: it is our team work.

Takao: Chika knows everything from sales manager's request to urgent production.That makes the work easier. Also making umbrella needs many processes and we need to communicate clearly.

Sugaya: we also ask neighbor factories for sewing process. And we know each one's feature so that we ask this pattern to this craftsman, that pattern to that factory. That's how we make such variety!

Takao: I realize Makita staffs are neighbors and craftsman and factories are also neighbors!

Sugaya: This team work of neighborhood is our umbrella's secret to create perfect beauty and superior quality. As Takao is the professional of cutting parts, each craftsman is the professional of other processes. And we all know what others do and pass the baton to next process with care. That is the important basement of creating Makita's umbrella.

Chika: And the special of our umbrellas are using yarn dyes woven textiles.

Takao: There are the particular beauty only achieved by jacquard weaving.

Sugaya: our wish is to create umbrellas to draw the beautiful scenery when we feel down in the rainy days. And we are happy to see many umbrellas in the town with smile of people.

Other articles

織物職人とブランドの想いをつなぎカタチにする:藤江

>記事を読む

傘づくりを通して学んだ織物の魅力と面白さ:瀧口里香

> 記事を読む

What is the customer service at Makita Shoten like from the sales team?

> Read article

Interview with the planning team about working at Makita Shoten

> Read article

Connecting generations from the 5th generation to the 6th generation and into the future

> Read article

新しい時代へと進化していく槙田商店のテキスタイル